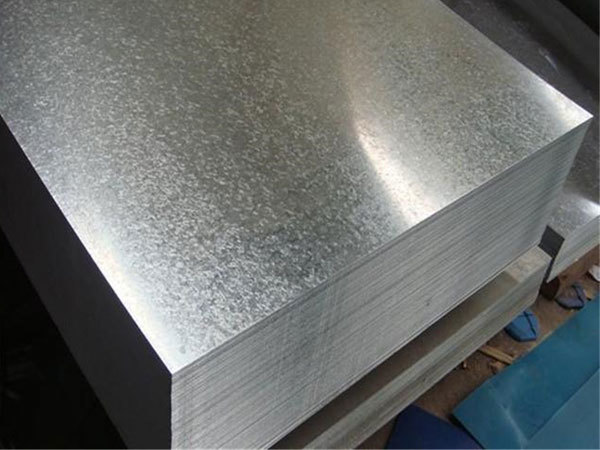

Appearance differences of galvanized sheet

Surface condition: Due to different treatment methods in the coating process, the surface condition of galvanized sheets also varies, such as ordinary zinc flakes, fine zinc flakes, flat zinc flakes, zinc free flakes, and phosphating treated surfaces. German standards also specify surface levels.

On the basis of galvanized coil, it is coated with color paint with certain technology to give more color to the product. The colorful and beautiful surface makes it more widely used

16

2022

/

09

Do you know how to polish carbon steel plates

Quality cannot be guaranteed. Manual polishing cannot guarantee the uniformity and thoroughness of polishing, which will affect subsequent bending, spraying and other processes, and affect the overall appearance and internal quality of the product.

16

2022

/

09

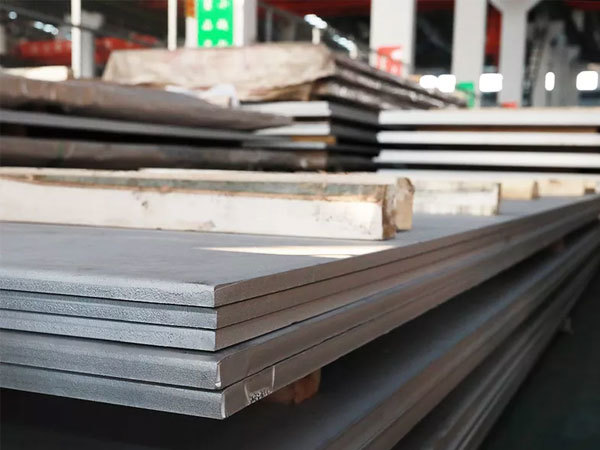

Classification of carbon steel

Low carbon steel has a carbon content of 0.04-0.3%, which is the most common carbon steel grade. Low carbon steel is also considered low carbon steel because it is defined as having a low carbon content of 0.05-0.25%. Low carbon steel has ductility and high plasticity, and can be used for automotive body parts, sheet and wire products. In the high-end range of low carbon content, coupled with up to 1.5% manganese, mechanical properties are suitable.

16

2022

/

09

Process principle of galvanized coil

Process principle: In a rotating drum containing plated parts, glass balls, zinc powder, water, and accelerator, the glass balls, as the impact medium, rotate with the drum, causing friction and hammering with the surface of the plated parts to generate mechanical and physical energy. Under the action of chemical accelerator, the coated zinc powder is "cold welded" to the surface of the plated parts, forming a smooth, uniform, and fine coating with a certain thickness.

16

2022

/

09